Measuring Metallic Corrosion with Half Cell Potential Test

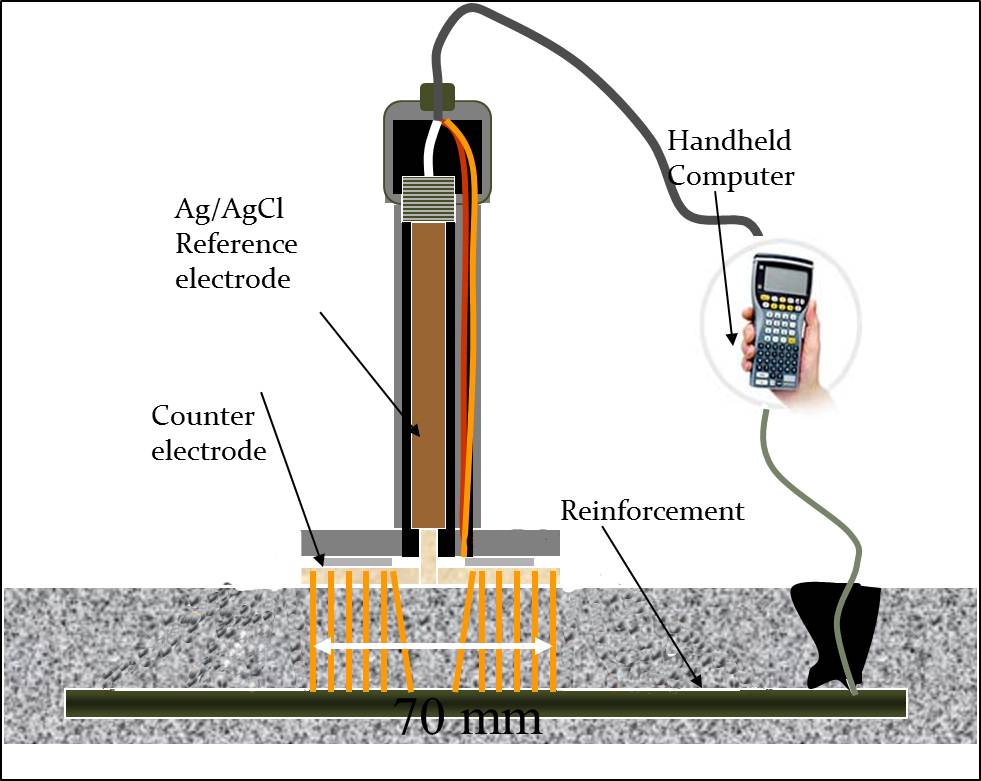

When reinforcing

steel corrodes inside concrete, an electro-chemical process occurs and its

characteristics can be identified with a half-cell potential (HCP) measurement,

also known as a ‘half cell potential test’. HCP measures metallic corrosion to

determine the regions of potential corrosion and the risk it can impose on the

structure. Date interpretation is nuanced and specific to particular sites, but

generally a more negative potential means a risk of corrosion occurring in

unsaturated marine exposed concrete. To conduct the test, an electrode is used

to form one part of the bimetal cell, while the reinforcing steel within the

concrete serves as the other half. Silver/silver chloride in a potassium

chloride solution or a simple Copper/Copper Sulphate cell is the ideal

reference electrode for use on-site. An electrode that is made of copper/copper

sulphate is widely used, too.

An advanced half cell

potential meter is a great instrument to have for a more reliable way to locate

corrosion in embedded reinforcing steel. The best meters are versatile and can

work with either a silver/silver chloride or copper/copper sulphate half-cell.

Cover concrete is

locally removed over an appropriate bar, and the electrical connection is

established to the steel. During the test, you need to ensure electrically

continuous steel by determining the resistance between the two points which are

widely separated. The reinforcing bar is linked to a half-cell through a

meter’s internal digital voltmeter and readings of the half-cell potential are

identified about regular grid points to create a prospective map of the area.

Advanced machines may offer a wheel electrode for quick data collection.

Operators may plot

contour lines between the points of equal potential while measuring

metallic corrosion with a half cell potential meter. That way they can

indicate that those areas possess the highest risk of corrosion. It is

recommended that you expose and inspect reinforcing steel in places where low

and high risks of corrosion exist as a final point of data to confirm an

inspection method. That way, you can estimate the rate of corrosion and

evaluate the need for repair or further investigation.

Comments

Post a Comment